Short Lead Time for Waste Plastic Recycling - PET Washing Line – Grace

Short Lead Time for Waste Plastic Recycling - PET Washing Line – Grace Detail:

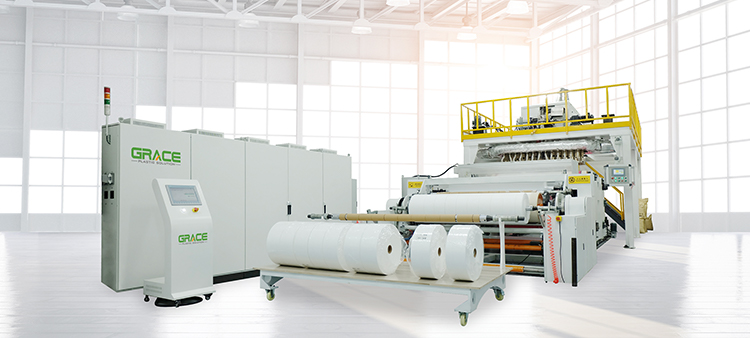

With improvement of the human environmental awareness, We are paying more attentions to the carbon emissions, PET material recycling become to first priority of us,Grace R&D automatic washing recycling production system with variety of design technology and modular construction, according to the regional situation of raw material , differences between production areas, products quality requirements and investment budget, applicable to bottle to bottle grade, sheet package grade and fiber (PSF) grade production Currently available capacity up to 6000 kg/h.

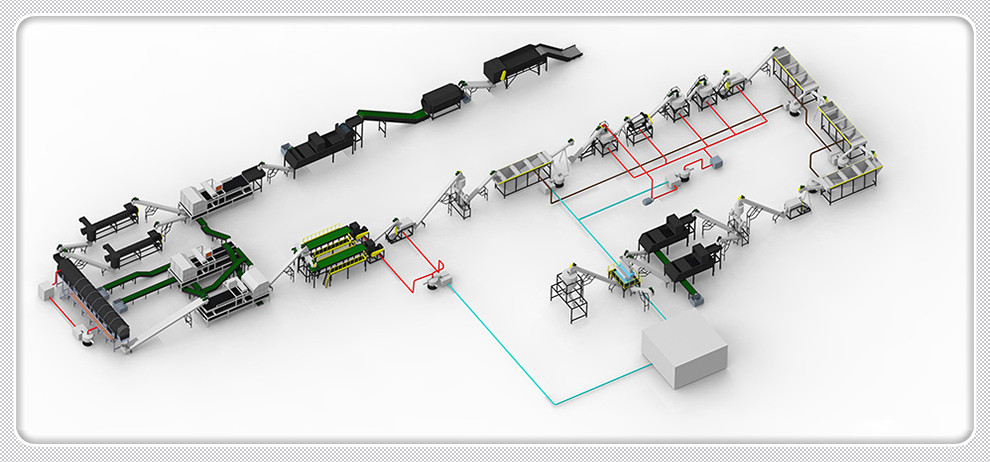

1. High automation, Less man power, low energy consumption, high output

2. Provide whole solution for by-products during production, for example: variegated bottles, non-PET material, sewage water, labels, caps, metal and etc.

3. With a materials pre-treatment system such as Pre-washer, Label processing module, highly improve quality of end products

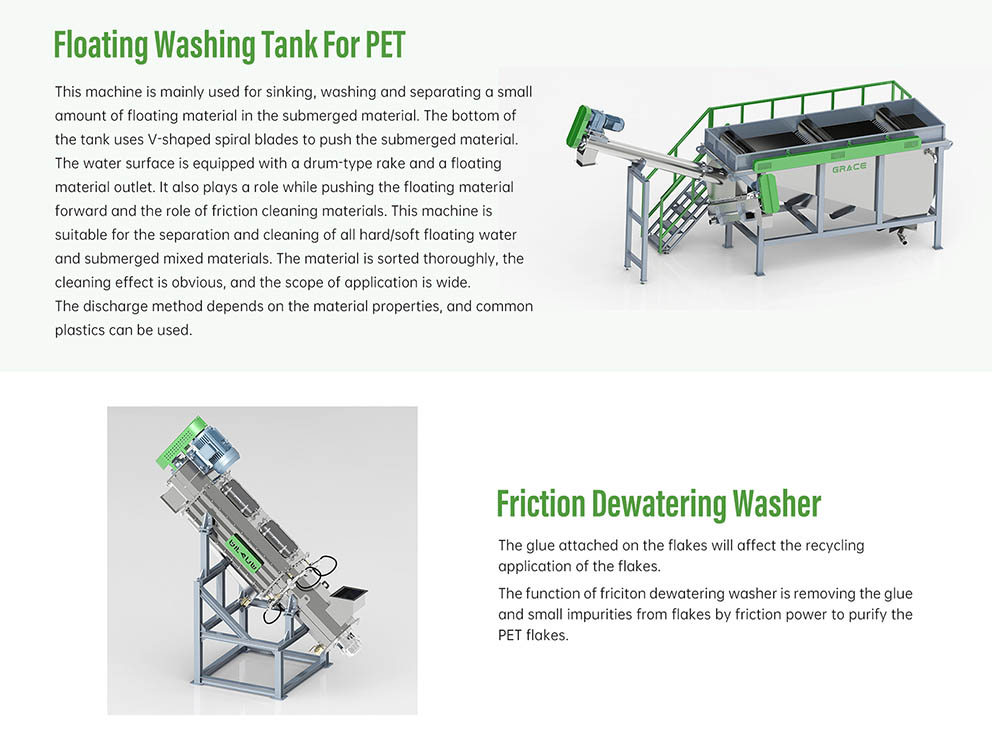

4. Through multiple cold flotation, hot washing and friction washing, fully remove the impurities, such as glue, organic and inorganic residue

5. The reasonable process design, reduce maintenance cost and bring convenient operation

Value advantage

Technical parameter

“B to B”Grade PET Bottle Washing Line

|

Model |

Capacity |

Consumption |

Steam |

Detergent |

Water |

Installation Power |

Space |

Man Power |

|

PET500 |

500 |

110 |

500 |

10 |

0.7 |

220 |

700 |

6 |

|

PET1000 |

1000 |

170 |

600 |

14 |

1.5 |

395 |

800 |

6 |

|

PET2000 |

2000 |

340 |

1000 |

18 |

3 |

430 |

1200 |

8 |

|

PET3000 |

3000 |

460 |

1200 |

28 |

4.5 |

590 |

1500 |

8 |

|

PET6000 |

6000 |

680 |

1500 |

50 |

8 |

850 |

2000 |

12 |

Fiber Grade PET Bottle Washing Line

|

Model |

Capacity |

Consumption |

Steam |

Detergent |

Water |

Installation Power |

Space |

Man Power |

|

PET500 |

500 |

70 |

300 |

10 |

0.7 |

190 |

500 |

10 |

|

PET1000 |

1000 |

140 |

500 |

12 |

1.5 |

340 |

700 |

12 |

|

PET2000 |

2000 |

280 |

800 |

15 |

3 |

390 |

1000 |

16 |

|

PET3000 |

3000 |

350 |

1000 |

25 |

4.5 |

520 |

1200 |

18 |

|

PET6000 |

6000 |

590 |

1200 |

40 |

8 |

920 |

1500 |

30 |

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Short Lead Time for Waste Plastic Recycling - PET Washing Line – Grace , The product will supply to all over the world, such as: Kuala Lumpur, Victoria, Guatemala, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.