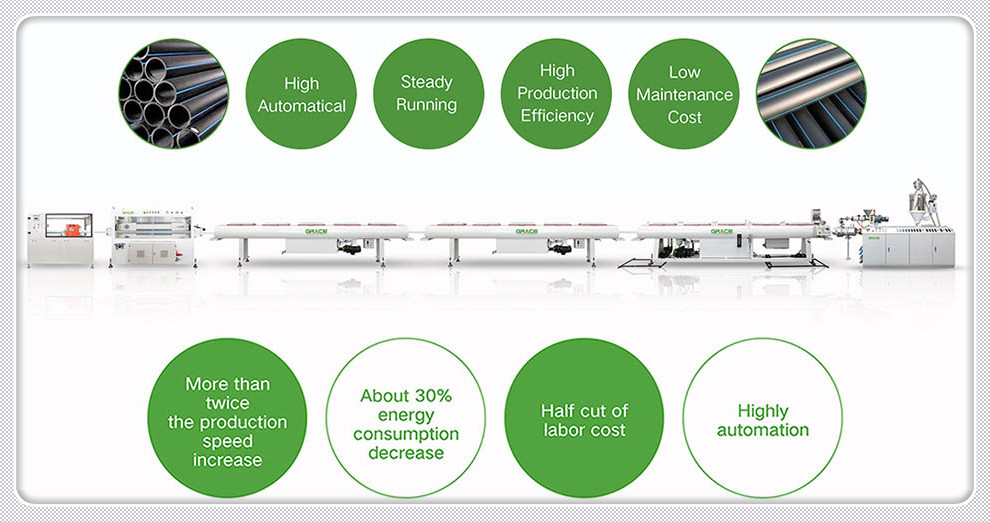

Short Lead Time for Plastic Rubber Band Extrusion Machine - HDPE Pipe Extrusion Line – Grace

Short Lead Time for Plastic Rubber Band Extrusion Machine - HDPE Pipe Extrusion Line – Grace Detail:

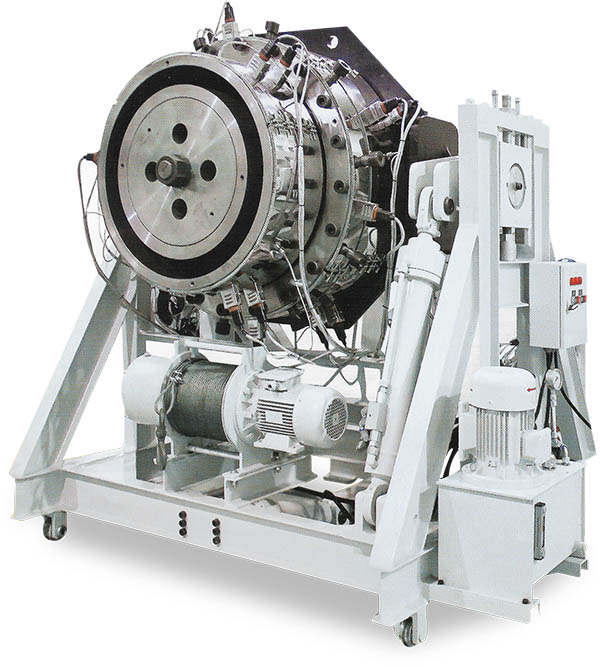

Single Screw Extruder

Siemens PLC Control System

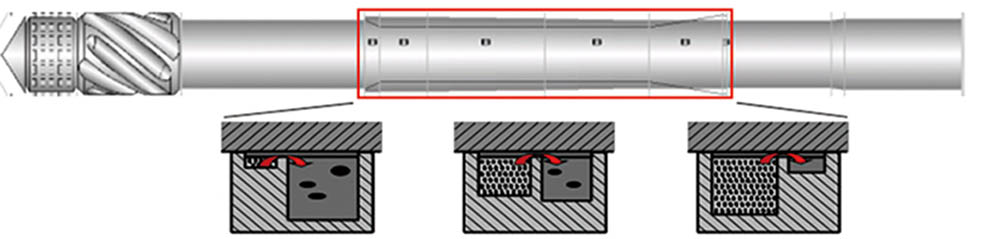

High Efficiency Screw / Barrier Zone

Solid channel:

Channel depth changes with plasticizing precess, plasticized material overflow into liquid channel through the gap between screw dam flight and barrel.

Liquid channel:

Melt pressure is lower, melt temperature increasing slower

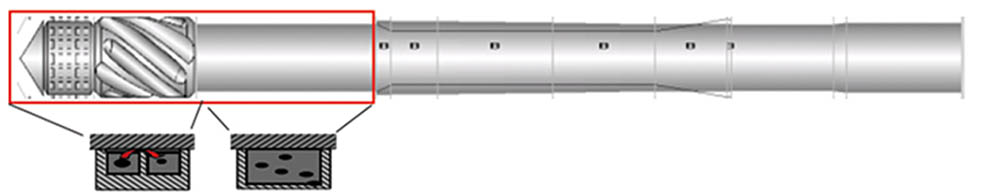

Shearing & Mixing Zone

Shearing and mixing zone:

Highly mixing of residual solid scraps and melt material

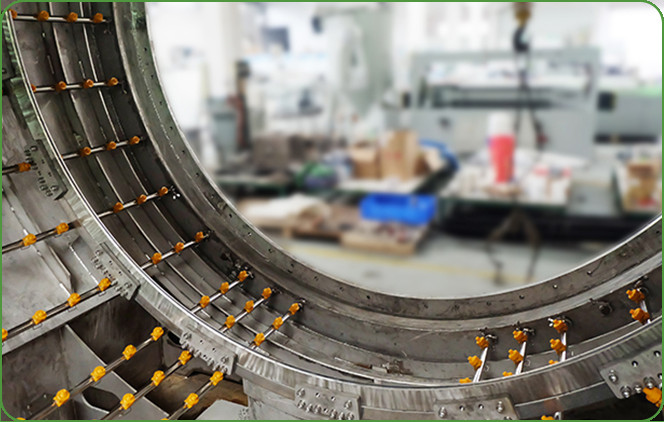

Die Head

■ Extrusion head with spiral structure, make sure the melt in side distributed evenly so as to achieve best plasticization.

■ Calibrator design with water ring which is easy to clean, to achieve bettercooling and then fast forming

Vacuum Tank

Advanced pipe line layout design and adjustable spray angle for better cooling effect, dense pipe line in the first zone for fast cooling.

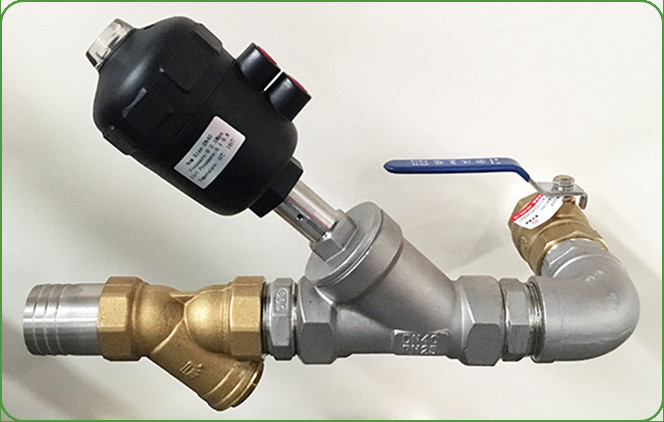

Flowmeter

Accurate control for calibrator’s

water supplement.

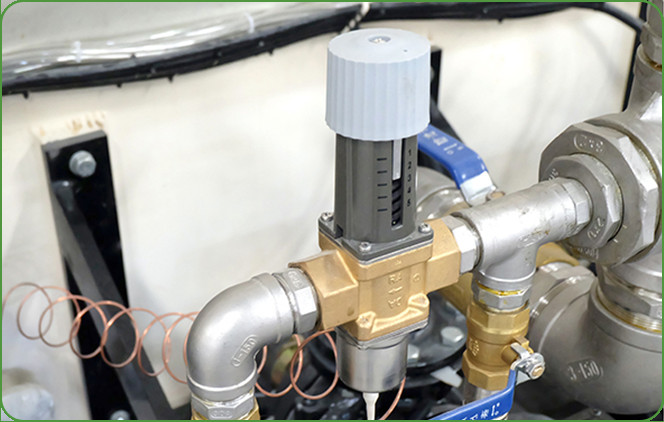

Pressure Protection System

Automatically and manually adjust

vacuum tank internal pressure

Water Level Control

Point-contact floating ball for

water level control.

Puissant Precool Ring

Puissant precool ring set in the

entrance of vacuum tank, brings

good cooling effect when pipes

move into the vacuum tank.

S.S. Semicircle Sliding Plate

Pipe supporting adopts S.S.

semicircle sliding plate, high

intensity supporting.

Gas, Water Separator

Avoid air flow back pressure

affecting other pipelines.

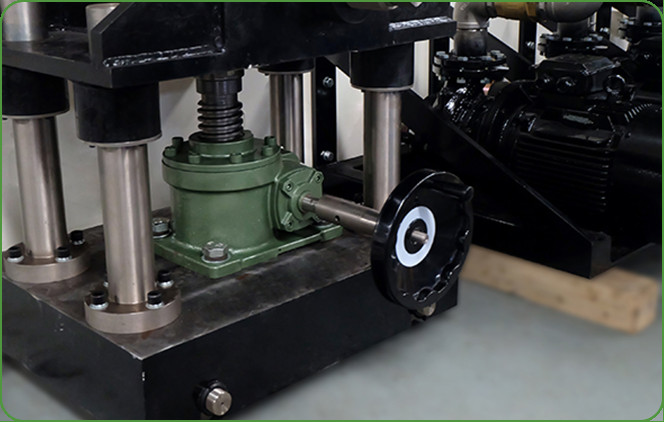

Turbine Screw Lifter

4 directions convenient

adjustment, turbine lifter

adjustment for up & down,

pulley adjustment for left & right.

Temperature Control Drainage

Danfoss expansion valve

temperature-controlled

drainage.

Water Inflow control

Both automatically and manually

for appropriate water level.

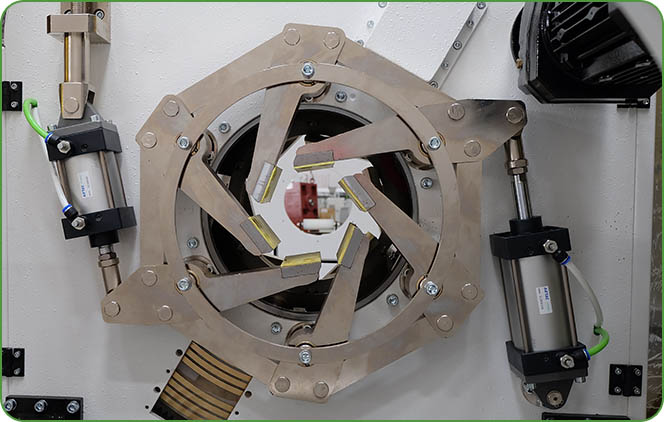

Haul-off Unit

For the different pipe size and different speed requirement, Grace developed kinds of haul-off unit accordingly.

Optional to choose multi-caterpillar haul-off unit with wide speed range.

Each caterpillar is controlled

by independent motor,

optional servo motor guarantee

speed uniformity.

Equipped with chain off and

nylon baffle, which adopts ultrahigh

PE material, to prevent the

damage from rubber block slack

and off tracking.

Different quantity caterpillar

shift, high friction rubber.

Cutter

Cutter is synrhonizedly controlled by servomotor to make sure precise cutting length.

Universal clamp

Coiler

40 Type Single/Double Station Coiler

63 Type Single/Double Station Coiler

110 Type Single Station Coiler

Grace offers different solutions according to

different required speed.

Siements PLC automatic operation mode.

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Short Lead Time for Plastic Rubber Band Extrusion Machine - HDPE Pipe Extrusion Line – Grace , The product will supply to all over the world, such as: Congo, Stuttgart, Sao Paulo, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!