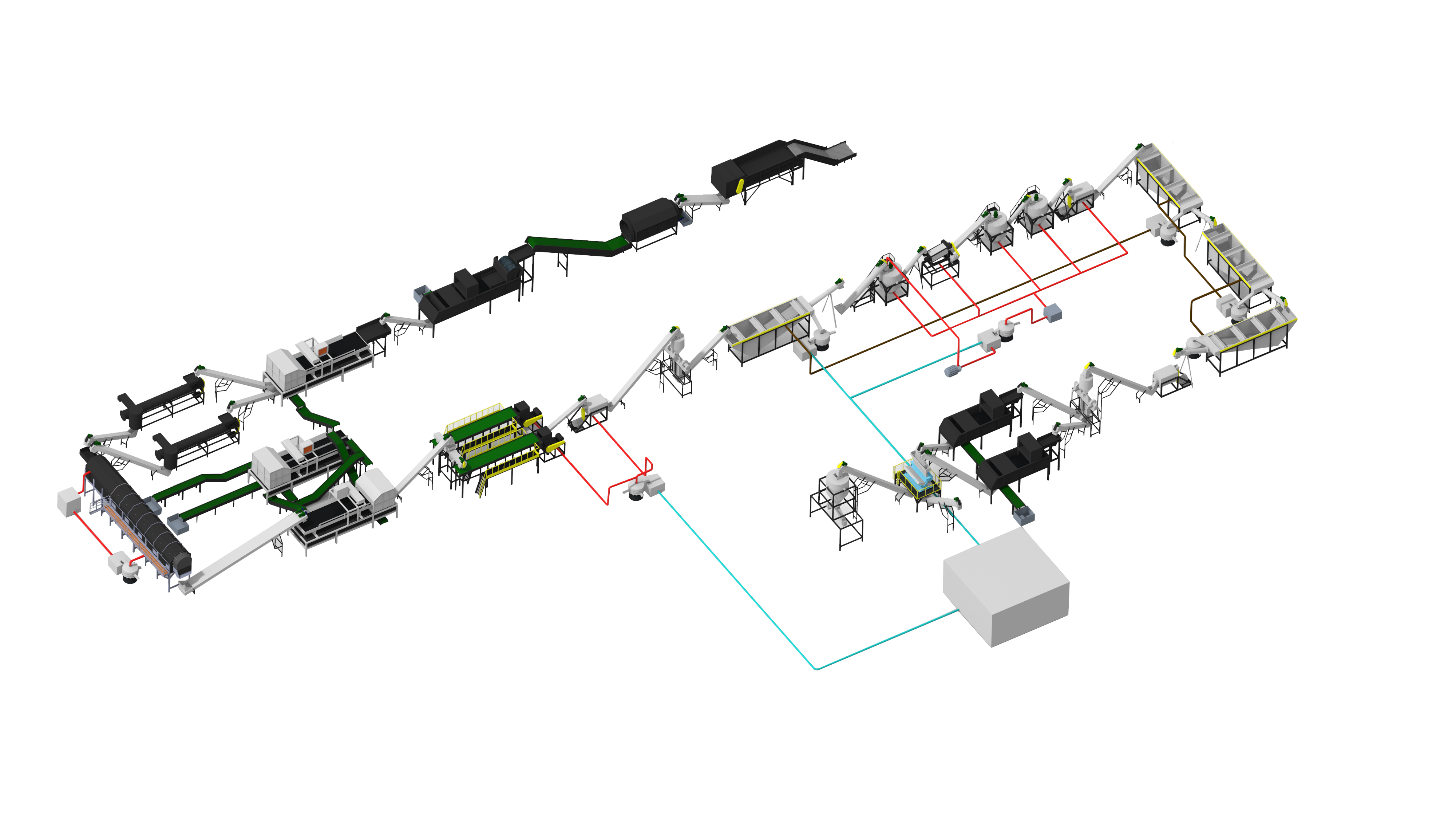

PET Bottle Recycling System

PET Bottle Recycling System

Application scope of Production line

Recycling PET bottle bales, PET sheets, and PET packaging tapes.

Downstream Applications

Recycled PET (rPET) for food-grade, bottle-grade, long/short fibers, sheets, packaging tapes, construction materials, etc.

|

Model |

Capacity (kg/h) |

Consumption (kw/h) |

Steam (kg/h) |

Detergent (kg/h) |

Water (ton/h) |

InstallationPower (kW) | Space(㎡) | Man Power (persons/shift) |

|

PET500 |

500 |

70 |

300 |

10 |

0.75 |

190 | 600 | 4 |

|

PET1000 |

1000 |

140 |

500 |

12 |

1.5 |

340 | 800 | 4 |

|

PET2000 |

2000 |

280 |

800 |

15 |

3 |

390 | 1000 | 6 |

|

PET3000 |

3000 |

350 |

1000 |

25 |

4.5 |

520 | 1200 | 7 |

|

PET6000 |

6000 |

590 |

1200 |

40 |

9 |

920 | 2000 | 11 |

Technical Features:

1. Meets requirements for standard, 3A, and food-grade PET flake recycling.

2. Online water recovery system with 98% wastewater recycling.

3. Centrifugal and thermal drying keeps product moisture below 1%.

4. Optional additive recovery system enhances product value.

5. Various sorting equipment options ensure 99.5% purity in color and material.

6. Fully automated with adaptive adjustments.

7. Remote support and OTA upgrade services available.