PP/PE Granulation line

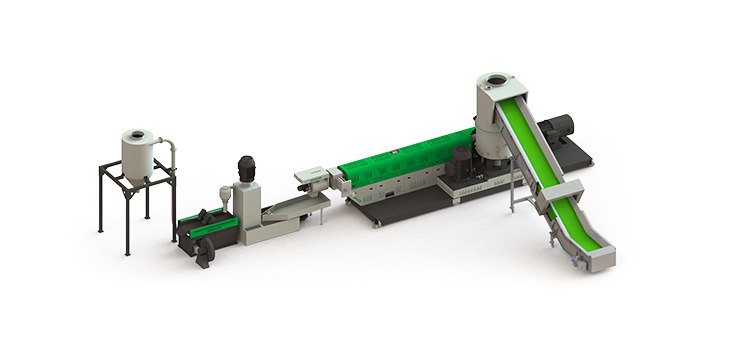

Film Agglomeration and Pelletizing Line – Double-Stage

Features:

1. Efficient Processing: Handles high-moisture, dirty raw materials with multiple filtration and dewatering steps.

2. Versatile: Processes LDPE, PP, films, fibers, waste silk, non-woven fabrics, and hard materials with auxiliaries.

3. Flexible Configuration: Customizable based on raw material and customer needs.

4. High-Quality Components: Made with durable materials like 38CrMoAlA, Cr12MoV, and stainless steel.

Advantages:

1. Enhanced Quality: Removes impurities and moisture, improving product purity.

2. High Capacity: Maintains productivity with complex raw materials.

3. Reduced Screen Changes: Efficient screen changers minimize downtime.

4. Customized Services: Tailored configurations for optimal performance.

5. Eco-Friendly: Energy-efficient design reduces consumption and pollution.

Additional Highlights:

1. Screen Changer: Flexible options for different raw materials.

2. Water Ring Cutting: Stable cutting with adjustable die face holes.

3. Air-Fed Hopper: Smooth feeding with adjustable fan power.

4. String Granulation: Alternative to water ring cutting.

5. Water Tank and Blower: Ensures quick drying and conveying.

Technical parameter

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuun |

Screw Changer |

Water-ring |

Cold Strand |

Underwater |

|

120+120 |

350-400 |

0.2-0.35 |

90-110/22-30 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

|

150+150 |

500-700 |

0.2-0.35 |

132-185/45-55 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

|

180+200 |

750-1200 |

0.2-0.35 |

250-355/90-110 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

|

200+200 |

1200-1500 |

0.2-0.35 |

315-400/110-132 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

Film Agglomeration and Pelletizing Line-Single Stage

Features:

1. Versatile Application: Perfect for recycling LDPE, PP, films, fibers, and more.

2. Configurable Flexibility: Can be adapted to process hard materials with added auxiliary equipment.

3. Efficient Filtration: Ensures high product quality despite primarily being used for cleaner materials.

4. Customizable Design: Tailored to customer specifications and material characteristics.

Advantages:

1. Cost-Effective: Especially suitable for cleaner, drier materials and budget-conscious customers.

2. Ease of Maintenance: Simpler structure for straightforward operation and maintenance.

3. Stable & High Efficiency: Advanced equipment like continuous screen changers and water ring granulators ensure productivity.

4. Durable Materials: High-quality components such as 38CrMoAlA die faces, Cr12MoV cutting blades, and stainless steel barrels.

5. Eco-Friendly: Designed to reduce energy consumption and environmental impact.

Additional Highlights:

1. Screen Changer: Larger size reduces the need for frequent changes.

2. Water Ring Granulation: Customizable die face structure for increased production volumes.

3. Hopper: 1-cubic-meter capacity with adjustable fan power for smooth feeding.

4. String Granulation Option: Alternative granulation method to meet diverse customer needs.

5. Water Tank: Adjustable and mobile for ease of operation and maintenance, made of durable stainless steel.

Technical parameter

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuun |

Screw Changer |

Water-ring |

Cold Strand |

Underwater |

|

120 |

350-400 |

0.2-0.35 |

90-110 |

28-36 |

Single/Double |

Option |

Option |

Option |

Option |

|

150 |

500-700 |

0.2-0.35 |

132-185 |

28-36 |

Single/Double |

Option |

Option |

Option |

Option |

|

180 |

800-1200 |

0.2-0.35 |

250-355 |

28-36 |

Single/Double |

Option |

Option |

Option |

Option |

|

200 |

1200-1500 |

0.2-0.35 |

315-400 |

28-36 |

Single/Double |

Optio |

Option |

Option |

Option |

Rigid Flake Pelletizing Line

Features:

Versatile Applicability: Suitable for recycling various hard miscellaneous materials, including HDPE.

Efficient Filtration: Equipped with a system to filter and purify plastics, eliminating impurities and moisture.

Particle Uniformity: Processes raw materials into consistent-sized particles.

Flexible Configuration: Offers single-stage or double-stage granulation based on material and customer needs.

Advanced Equipment: Utilizes advanced screen changers and pelletizers for stability and efficiency.

High-Quality Materials: Key components are made of durable, reliable materials.

Advantages:

Improved Quality: Enhances product quality through effective filtration and moisture removal.

Cost-Effective: Reduces costs while maintaining high productivity.

Eco-Friendly: Reduces energy consumption and environmental pollution.

Customizable: Tailored to meet customers’ specific needs and budgets.

Technical parameter

Single Stage

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuum |

Water-ring |

ScreenChanger |

Cold Strand |

Underwater |

|

120 |

350-400 |

0.2-0.35 |

90-110 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

|

150 |

500-700 |

0.2-0.35 |

132-185 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

|

180 |

700-1200 |

0.2-0.35 |

185-355 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

|

200 |

800-1500 |

0.2-0.35 |

200-400 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

Double Stage

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuum |

Water-ring |

ScreenChanger |

Cold Strand |

Underwater |

|

120+120 |

350-400 |

0.2-0.35 |

90-110/22-30 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

|

150+150 |

500-600 |

0.2-0.35 |

132-185/45-55 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

|

180+200 |

700-1200 |

0.2-0.35 |

185-355/90-110 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

|

200+200 |

800-1500 |

0.2-0.35 |

200-400/110-132 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

PVC Pelletizing Line

Features:

1. Advanced Cutting: Uses die-face hot cutting for UPVC & SPVC production.

2. Premium Materials: High-strength die face (38CrMoAlA) & durable blades (Cr12MoV).

3. Fine Surface Treatment: Chrome-plated & mirror-polished for corrosion resistance.

4. Flexible Batching: Complete process from batching to conveying.

Advantages:

1. Efficient & Energy-Saving: Boosts production while reducing costs.

2. Customizable: Tailors equipment to calcium carbonate content.

3. Effective Sieving: Avoids vibration screens for better efficiency.

4. Safe Storage: Designed for PVC’s heat sensitivity & high temperatures.

Technical parameter

|

Model |

Output |

Main Power |

Fan Power |

|

80/156 Conical |

300-400 |

55 |

3*3 |

|

92/188 Conica |

600-750 |

110 |

4*3 |

|

75/132 Conica |

600750 |

55-75 |

4*3 |

|

90/156 Conica |

850-1000 |

75-90 |

5.5*3 |

|

110/188 Conica |

1000-1200 |

110-160 |

5.5*3 |

|

120 Parallel |

800-1000 |

110 |

5.5*3 |

|

130 Parallel |

1200-1500 |

160 |

7.5*3 |