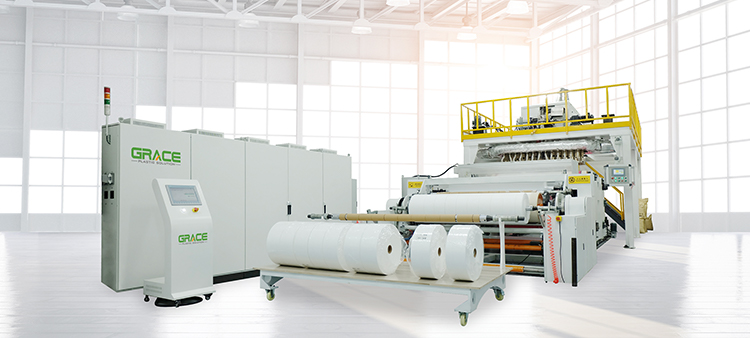

OEM/ODM Factory Multi-Layers Pe Pipe Extrusion Line - PVC Corrugated Tile Extrusion Line – Grace

OEM/ODM Factory Multi-Layers Pe Pipe Extrusion Line - PVC Corrugated Tile Extrusion Line – Grace Detail:

Product introduction

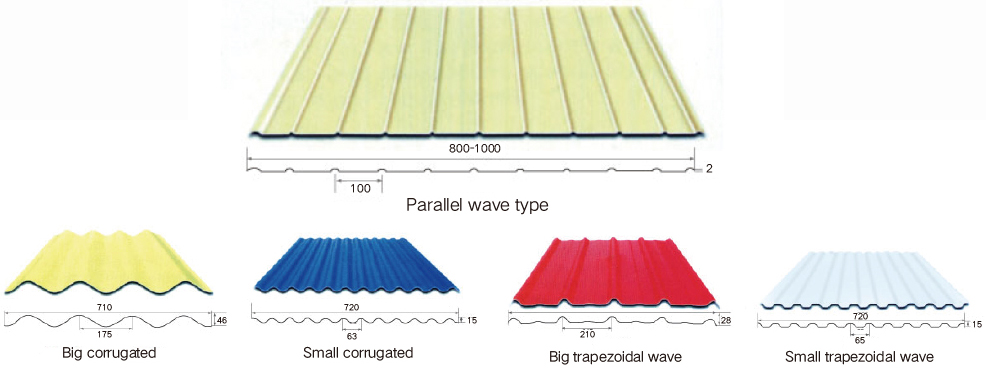

As a substitute of galvanized steel tile, corrugated tile get more and more extensive application in the building contruction, Grace customizes different solutions according to clients’demands on product structure, shape which has width from 720mm to 1130mm and thickness from 0 8mm to 3 0mm According to the exclusive preferences of different regions, Grace designs classical round wave type and trapezoidal shape Special alloy processed screw and barrel can meet 80-100phr high fill formula production requirements Calibration mould adopts special design of flow channel, increasing the space of cooling water and final product, which highly improving the cooling effect and forming speed, At the meanwhile, Dust-free cutter is perfect solution for roof tile cutting.

Value advantage

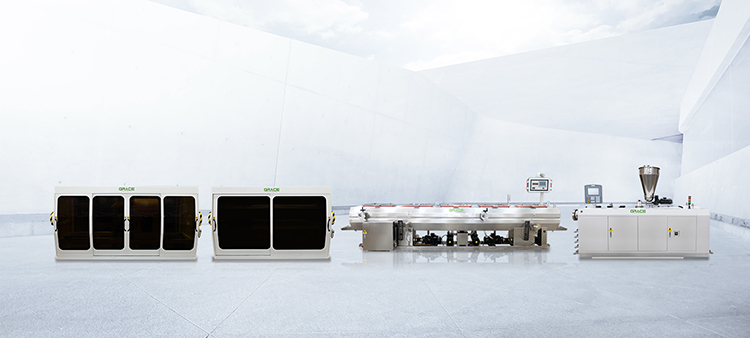

1. Special design of screw, which can ensure material perfect plasticizing and lower formulation cost; Depend on the request of high fill formula, SKD61(Japan or Germany) imported material with alloy sleeve treatment barrel can provide prefect solution.

2. Co-extruder equipped with dehumidifying and drying system can be applied to produce PMMA/ASA composite material, which ensures high performance and quality of final product.

3. T-die adopt hanger style can be applied to produce single PVC melt multi-layer material or multi layer compound material.

The mould flow surface adopts polish and electrochromism treatment, which ensure excellent liquidity and good anticorrosion, heat-resisting and wear resisting performance.

4. Distributor mostly applied in multi-layer compound process. It has Several structures such as A/B, A/B/A, A/B/C and etc. The main purpose is making perfect composition of different melting materials.

5. Calibration forming table includes three parts: calibration mold, haul off and cutter, Forming mould is made of Up and Down moulds, flow surface adopt polish and electrochromism treatment, which can ensure excellent liquidity and good anticorrosion, heat-resisting, wear-resisting performance.

6. The channel design is S shape to increases contacting surface of mould, which ensures faster heating transfer and quickly cooling calibration. In order to higher stable hauling, the shape of rubber roller(haul off) designs according to final product,The cutter adopt sawing type and the shape of blade designs according to final product, which ensuing flat and chip free cutting.

Technical parameter

| Structure | Material | Width | Thickness | Extruder Model | Designed Output |

| Single Layer | PVC | 720/920/1100/1130mm | 1.0-3.0mm | SJZ80/156 | 350-400kg/h |

| Double Layers | ASA/PMMA+PVC | 720/920/1100/1130mm | 1.0-3.0mm | SJ50/30+SJZ80/156 | 350-400kg/h |

| Triple Layers | ASA/PMMA+PVC+PVC | 720/920/1100/1130mm | 2.0-3.0mm | SJ50/30+SJZ65/132+SJ51/105 | 350-400kg/h |

| Triple Layers | PVC+PVC Foaming+PVC | 720/920/1100/1130mm | 2.0-3.0mm | SJ51/105+SJZ65/132+SJ51/105 | 350-400kg/h |

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for OEM/ODM Factory Multi-Layers Pe Pipe Extrusion Line - PVC Corrugated Tile Extrusion Line – Grace , The product will supply to all over the world, such as: Haiti, Iran, Netherlands, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

We have been looking for a professional and responsible supplier, and now we find it.