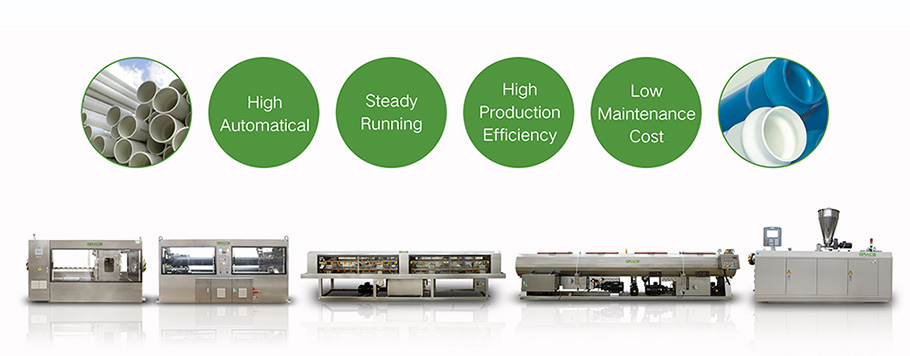

CPVC Pipe Extrusion Line

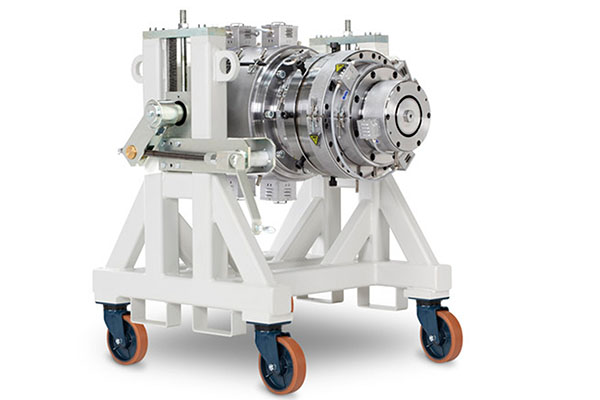

Conical Twin Screw Extruder

■ High-speed extrusion, with high capacity and low power consumption

■ Barrier design screw with asymmetric slotted barrel design

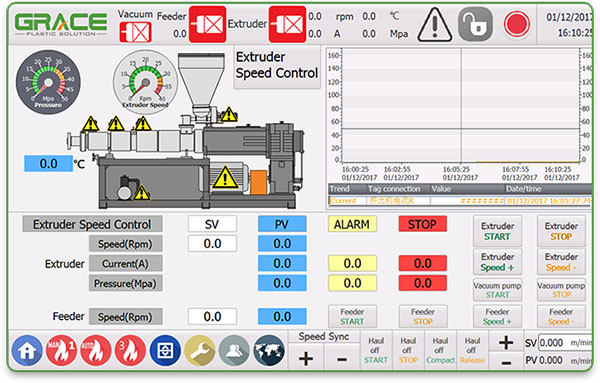

Siemens PLC Control System

■ Intelligent & centralized control;

■ Automatic preheating;

■ Diagnose function;

■ Remote monitoring;

■ Multiple-language;

■ Intelligent alarm system;

■ Formula management.

Optional: B&R Control System

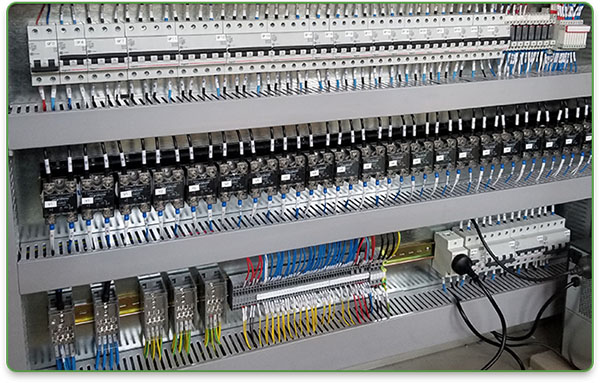

Standard Electrical Part

■ Siemens, ABB, Schneider, Dynisco, Omron, etc.

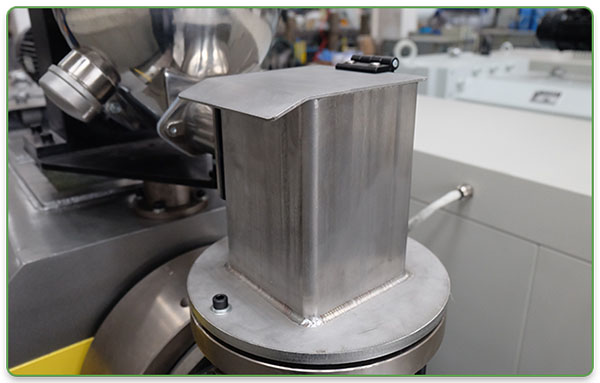

Twin-screw Feeder

Top brands: Siemens

Integrated vertical type gearbox

Flange surface by nickel-coating treatment

■ Prevent from material bridge;

■ High assembling precision;

■ High transmission efficiency;

■ High load capacity;

■ NSK/SKF bearing, ensure stabilization;

■ Oil temperature control;

■ Compact structure;

■ Avoid material leakage after long time usage.

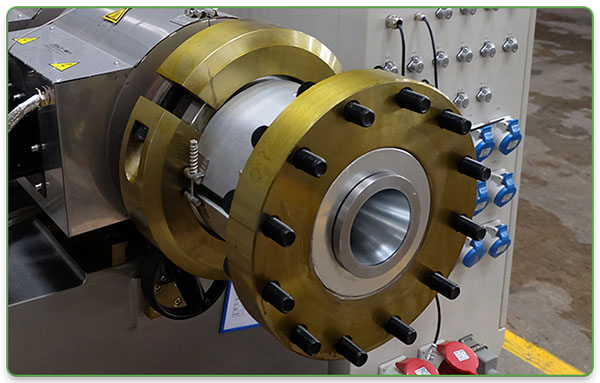

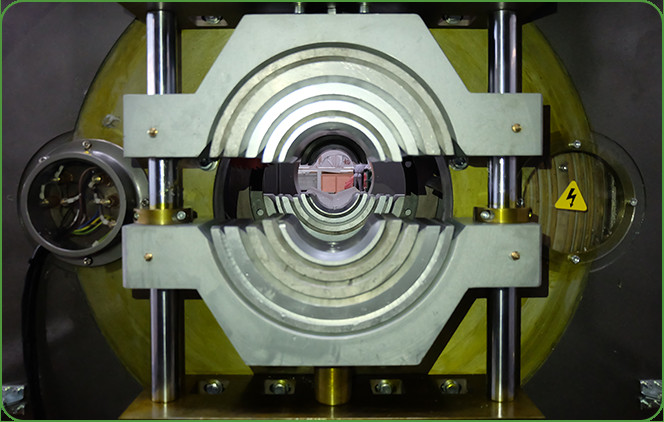

Die Head

■ Spacious flow channel design to guarantee high extrusion capacity and good melt.

■ Optimized temperature control and flow channel design, precise melt temperature control.

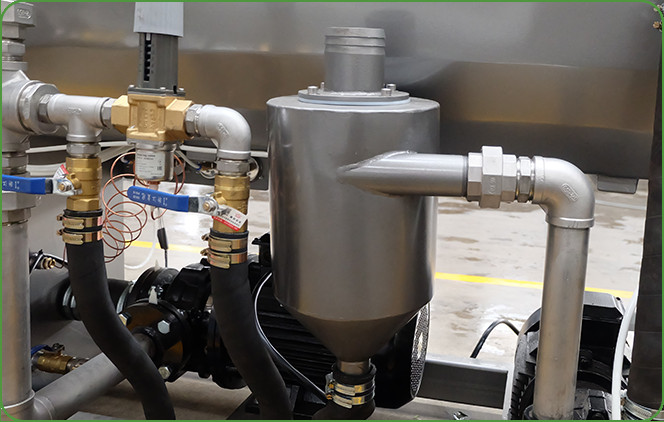

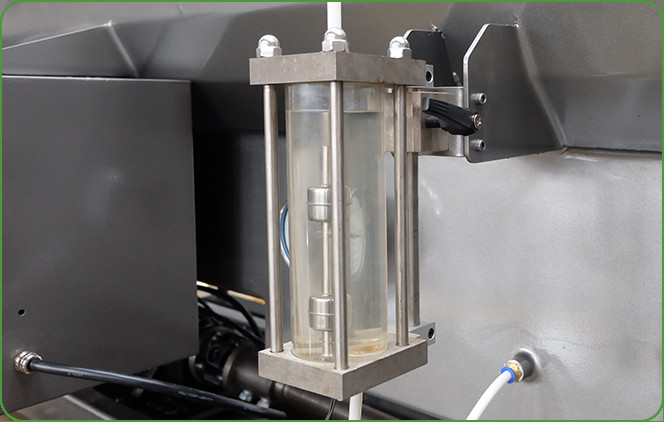

Vacuum Tank

Advanced pipe line layout design and adjustable spray angle for better cooling effect, dense pipe line in the first zone for fast cooling.

Two-loop Big Volume Filter

Gas, Water Separator

Danfoss Expansion Valve

Point Contacting Type

Water Inflow control

Spary Cooling System

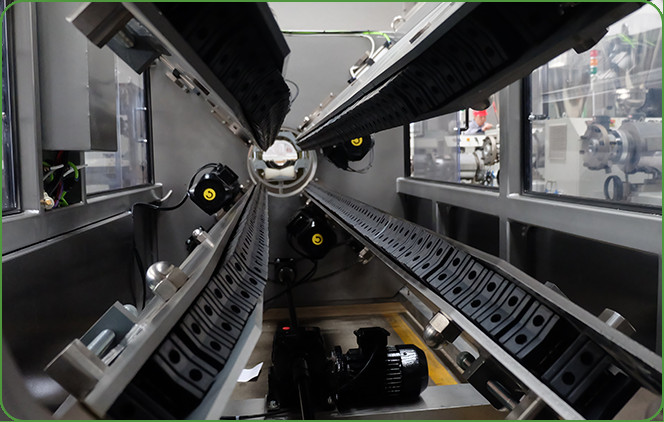

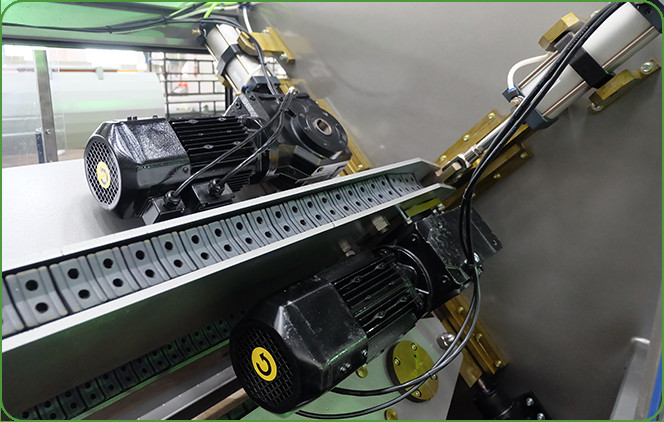

Haul-off Unit

For the different pipe size and different speed requirement, Grace developed kinds of haul-off unit accordingly.

The haul-off unit equiped with single motor drive or every caterpillar with seperate motor drive,there is the belt tyope haul-off unit, stable hauling.

For the large diameterpipe, a pipe winch device is equipped to the production line to reduced the waster material

Different quantity caterpillar

shift, high friction rubber.

Each caterpillar is controlled by

independent motor, optional

servo motor guarantee speed uniformity.

High-precision Encoder

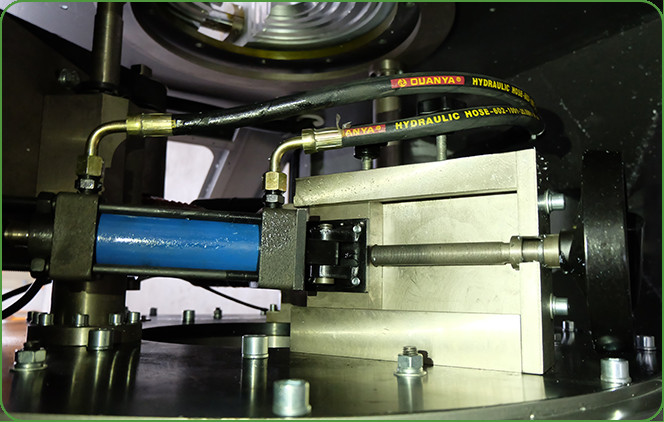

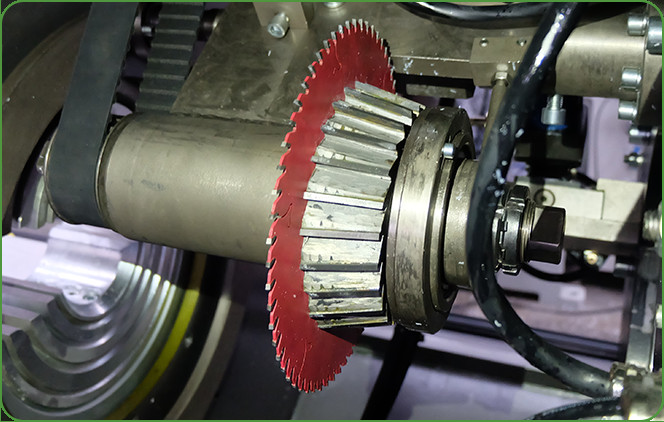

Cutter

New model of planetary cutting design, endurable, dust-collecting efficiently, and quiet.

Italian hydraulic system

Eccentric wheel

Chamfering function

Industry-leading aluminum

clamping locking design,largely

extends service life of clamping block

Belling Machine(Optional)

Automatic Online Socketing

High-efficiency Heating And Cooling

Belling