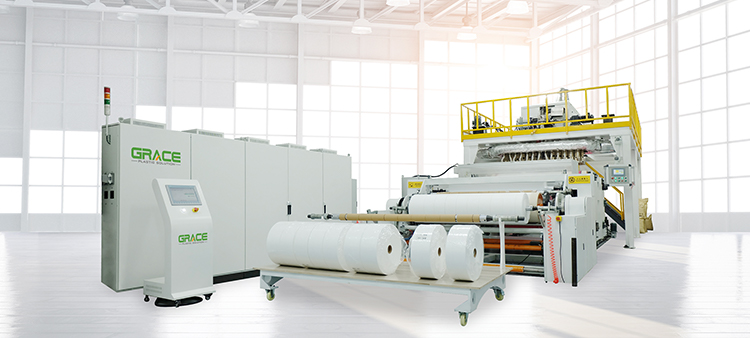

Bottom price Pe Foam Recycling Machine - PE/PP Films, Shopping And Woven Bags, Waste Fibers Granulation Line – Grace

Bottom price Pe Foam Recycling Machine - PE/PP Films, Shopping And Woven Bags, Waste Fibers Granulation Line – Grace Detail:

As plastic apply in more areas in the world, waste plastic recycling emerges due to different area ,cost and performance requirement Through Grace R&D efforts, We had developed plastic recycling and granulation machines to avoid environmental pollution caused by large amount of plastic’s burning or landfill, which significantly extends plastic’s usage cycle,Grace provide various options for customer, such as L D ratios, multiple exhaust screw structures, The master and secondary machines, several kinds of pelletizers, as well as 100-1000kg h line output can be provided

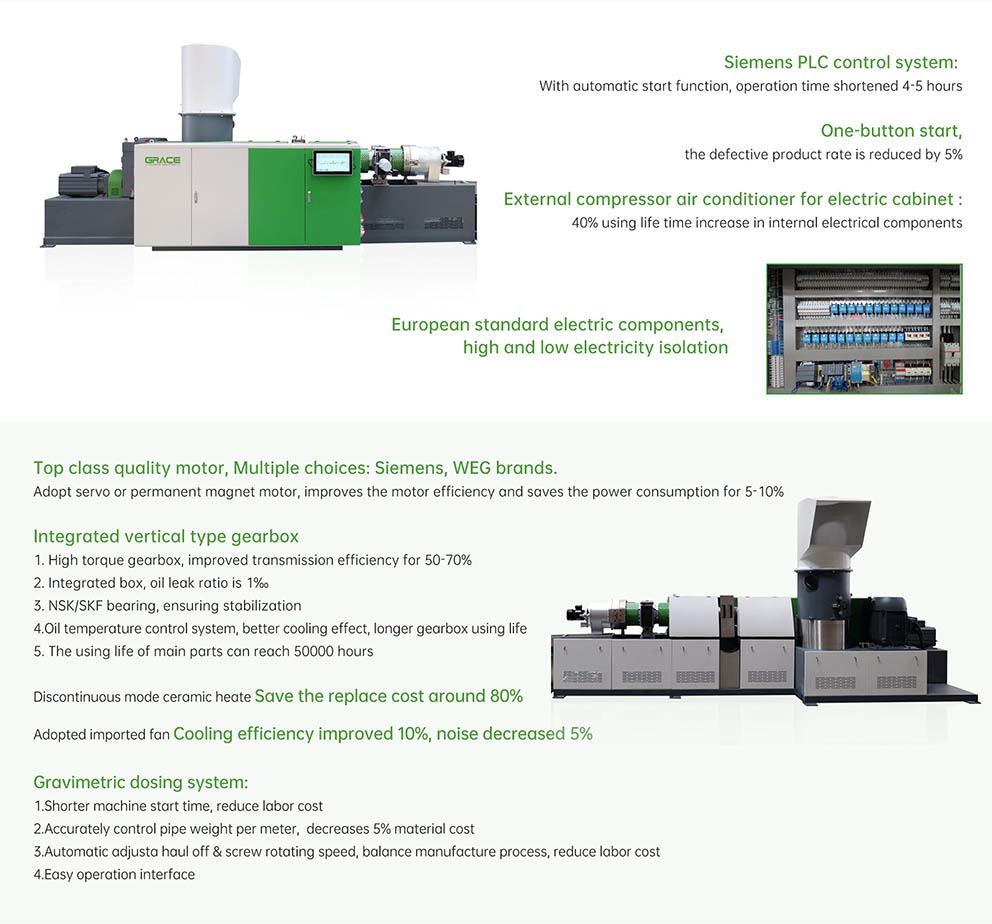

Value advantage

Technical parameter

Single Stage

|

Model |

Capacity |

Energy Consumption |

Main Power |

Screw Outer Diameter |

Vacuun |

Screw Changer |

Water-ring |

Cold Strand |

Underwater |

|

70 |

70-120 |

0.2-0.35 |

37 |

70(33:1) |

Option |

Standard |

Option |

Option |

Option |

|

100 |

200-250 |

0.2-0.35 |

90 |

100(30+35:1) |

Option |

Standard |

Option |

Option |

Option |

|

120 |

300-400 |

0.2-0.35 |

110 |

120(30+33:1) |

Option |

Standard |

Option |

Option |

Option |

|

150 |

500-600 |

0.2-0.35 |

132 |

150(30+32:1) |

Option |

Standard |

Option |

Option |

Option |

|

180 |

700-850 |

0.2-0.35 |

185 |

180(30+32:1) |

Option |

Standard |

Option |

Option |

Option |

Double Stage

|

Model |

Capacity |

Energy Consumption |

Main Power |

Screw Outer Diameter |

Vacuun |

Screw Changer |

Water-ring |

Cold Strand |

Underwater |

|

70+90 |

110-180 |

0.2-0.35 |

30+22 |

70(25+12:1) |

Option |

Standard |

Option |

Option |

Option |

|

100+120 |

200-300 |

0.2-0.35 |

75+37 |

100(25+12:1) |

Option |

Standard |

Option |

Option |

Option |

|

120+150 |

300-450 |

0.2-0.35 |

90+45 |

120(25+12:1) |

Option |

Standard |

Option |

Option |

Option |

|

150+180 |

500-650 |

0.2-0.35 |

110+55 |

150(25+12:1) |

Option |

Standard |

Option |

Option |

Option |

|

180+200 |

700-850 |

0.2-0.35 |

160+75 |

180(25+12:1) |

Option |

Standard |

Option |

Option |

Option |

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for Bottom price Pe Foam Recycling Machine - PE/PP Films, Shopping And Woven Bags, Waste Fibers Granulation Line – Grace , The product will supply to all over the world, such as: Singapore, Provence, Dubai, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.